Reciprocating Compressors

For many years, reciprocating compressors and their connected technologies have been among the main research field of the REASE Group, as testified by the intense relationships with industrial players of this sector like GE Oil&Gas or C.S.T. Compression Service Technology. In the framework of these collaborations, the main competences that have been acquired are:

-

Lumped parameter numerical models

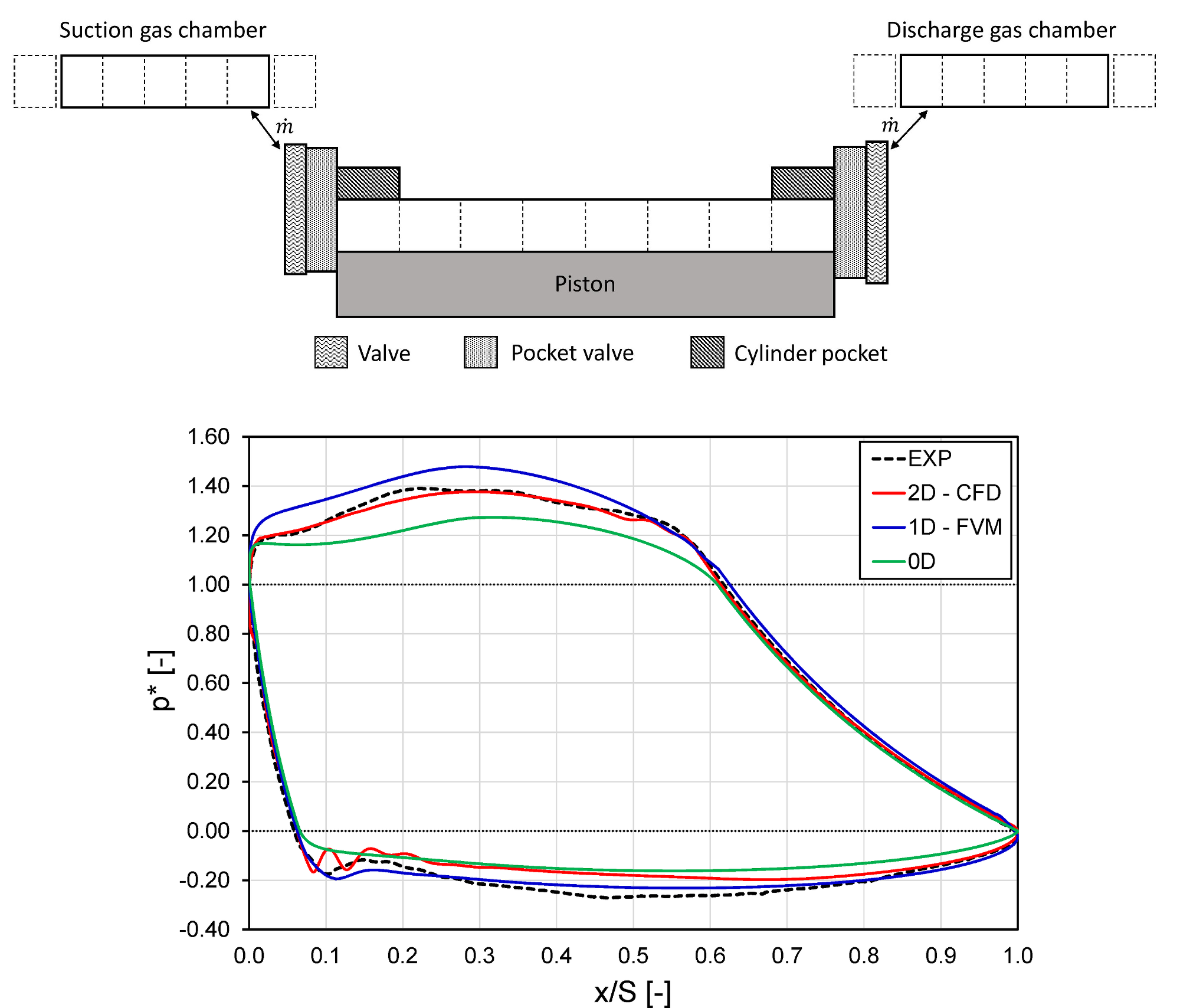

Development of a hybrid time-frequency domain lumped parameter model for the fluid-dynamic analysis of the full compressor-pipelines system. The reciprocating compressor thermodynamic cycle is simulated with a 0-D time-domain model; the pressure wave propagation in the pipelines is modelled by means of a transfer matrix approach in the frequency domain.

-

One-dimensional numerical models

Development of a 1-D numerical model of the reciprocating compressor that solves the fluid dynamic equations by applying the finite volume method (FVM).

-

3-D CFD analysis of reciprocating compressors valve system

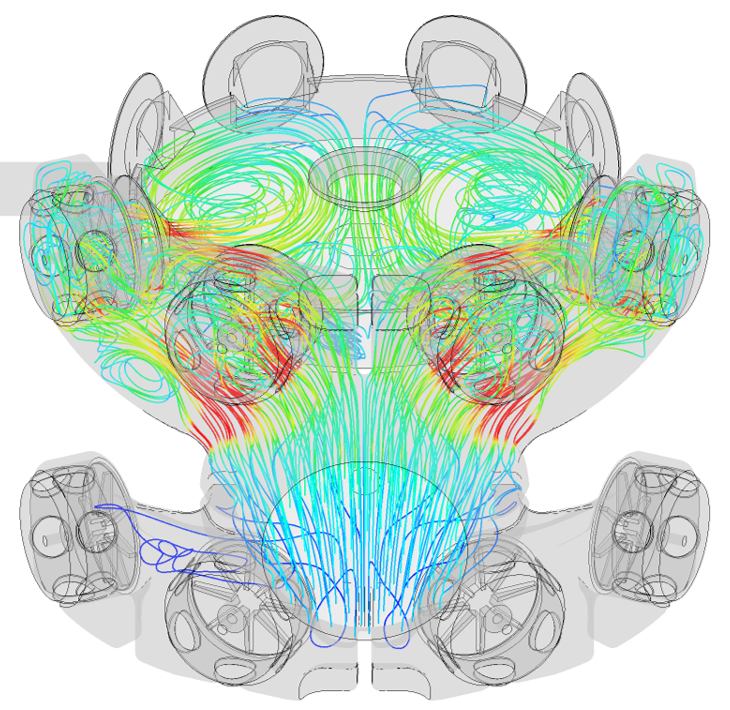

Innovative simplified 3-D CFD approach for the steady-state simulation of the gas passage through the inner paths of cylinders that allows substituting the real valve with an equivalent porous media, which ensures an acceptable accuracy of the pressure loss prediction and a substantial reduction of the computational cost.

-

CFD-based parametric analysis and optimisation

Definition of a procedure to simulate the whole fleet of GE Oil&Gas cylinders by means of parametric models.

-

Simulation of reciprocating compressors thermal behaviour

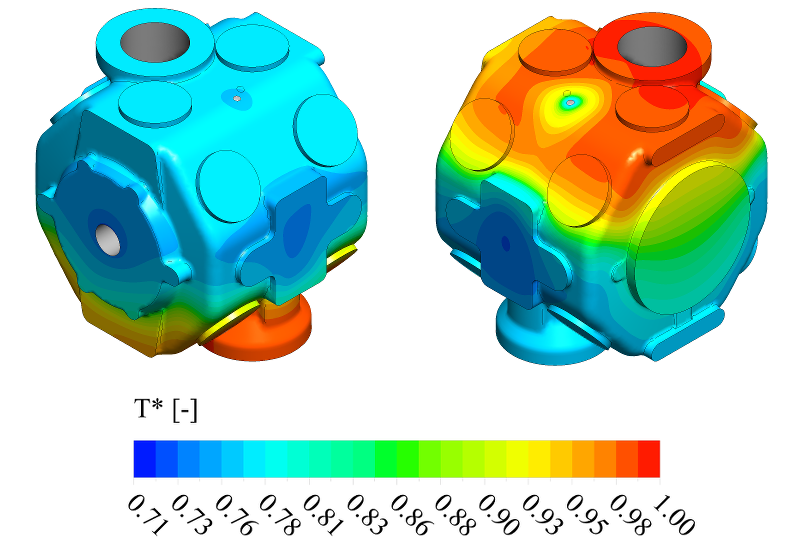

Implementation of a conjugate heat transfer (CHT) simulation on a double-acting reciprocating compressor cylinder to accurately predict both the thermal state of the compressor cylinder and the temperature field of the cooling water

-

2-D CFD modeling of reciprocating compressors transient behaviour

Transient 2-D CFD modelling strategy that enables the prediction of the working cycle of a reciprocating compressor, ensuring a compromise between the accuracy of the results and the simulation cost.

-

Unsteady CFD simulations of the dynamic motion of automatic valves

-

Dedicated valve flow test bench

Long experience in experimental tests on automatic valves for reciprocating compressors for the evaluation of the valves’ flow coefficient

-

Acoustic analysis of reciprocating compressors components

last update: 27-Sep-2022